W198 300SL

from Carburetors to Fuel Injection:

BRINGING the World's First SUpercar UP TO SPEED

It's hard to believe the W198 300SL debuted almost 70 years ago but even with it's numerous innovations and safety features, there was plenty to improve upon throughout its development.

Originally introduced with carburetors as the W194 racecar, fuel injection was introduced for the 1953 season and was used in the production vehicle, released in 1955, as well. Though complex and expensive, fuel injection provides better fuel economy, fewer emissions, and generally better performance, all important aspects of a high-performance sports car.

Fuel Injection Pumps for the

LEARN MORE ABOUT THE FUEL FEED PUMPS AT THE LINK BELOW

Flow Testing Quantities of The Bosch R3

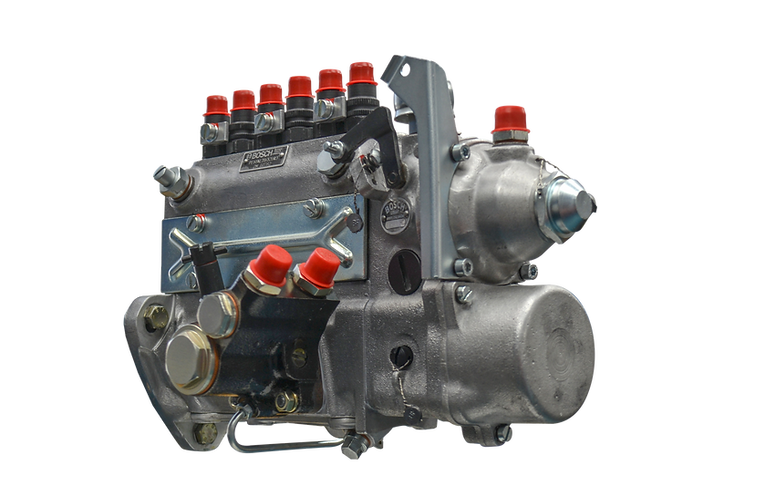

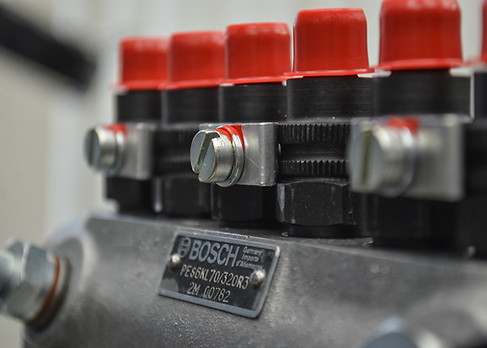

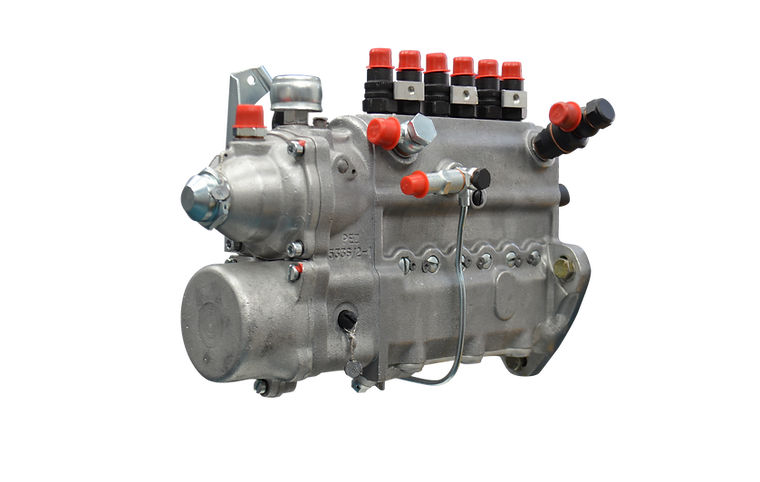

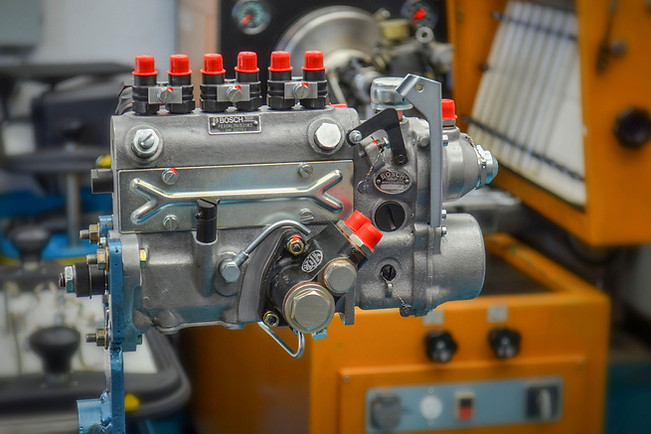

The PES6KL70/320 R3 seen here is a 6-plunger model which provided improved efficiency and allowed adjustments to individual plungers and, in effect, injectors. Its inline design and layout also carried over to later fuel injection pump development as seen in the W113 pumps from the 60s and 70s such as the R11, R18, and R20 series.

This pump is an example of a pneumatic governor pump. Check out the link at the bottom of the page for more info specific to pneumatic governor pumps. More on the PES6KL70/320 R2 and PES6KL70/320 R8 coming soon.

300SL Pumps

Bosch PES6KL70/320 R3

PRODUCED FROM 1955-1958

MODEL: W198 300SL "GULLWING"

The PES6KL70/320R3 is an example of a pneumatic governor pump and was produced for use in the famed W198 300SL Gullwings.

As fuel injection pumps continued to be improved upon they became the standard method of getting fuel to the engine over the decades with the inline setup becoming the go-to design for Mercedes-Benz vehicles moving forward.

LEARN MORE ABOUT THE FUEL FEED PUMPS At the link BELOW

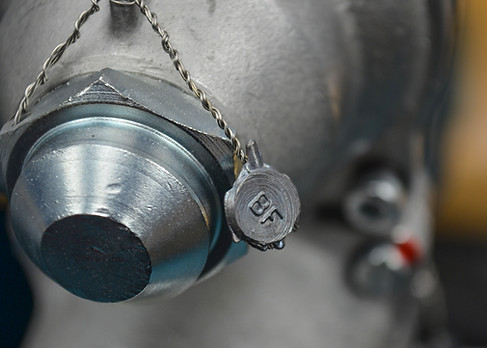

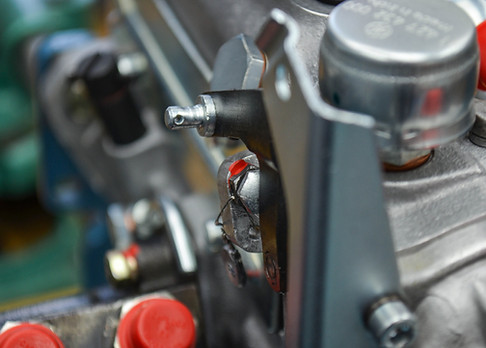

Here you can see an R3 during the reassembly process, displaying the inner workings of the pneumatic governor and camshaft. Below that you can see some comparison pictures of a purportedly restored R3, but with wear and grime that indicates a lack of disassembly, calling into question the quality and effectiveness of the previous restoration.

It's not just a "looks" thing either. Old gaskets and seals will result in leaks and suboptimal performance. Even worse, grit and grime can loosen and get injected directly into the engine, potentially causing damage or catastrophic issues.

Simply put: If you're not getting a fully restored fuel injection pump you're wasting time, money and opening a door to future issues.

300SL Pumps

Bosch PES6KL70/320 R8

PRODUCED FROM 1958-1963

MODEL: W198 300SL "ROADSTER"

The PES6KL70/320R8 is an example of a pneumatic governor pump and was produced for use in the famed W198 300SL Gullwings from 1958-1963.

Though similar to the previously seen R3, some differences include plunger guide screws returning to the front of the pump housing (seen above the viewing port) and the removal of inlets and outlets on the upper right and left of the front of the body.

This pump recently went through a deep clean in the ultrasound bath, media blasting, and hand polishing. The interior parts are due for the same process after which the pump will be reassembled and move on to the testing and calibration process.

Bosch 300SL Fuel Injection Pumps

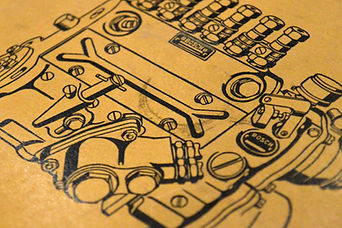

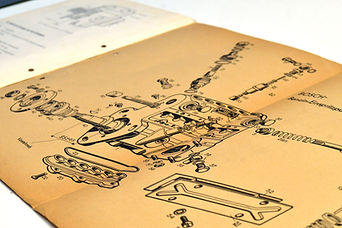

Vintage Documents

Getting the original supercar Running RIGHT

Believe it or not even aspects of the original supercar have fallen through the cracks. We see countless 300SL pumps that are in desperate need of work and often leave their cars running poorly, even if the owner isn't aware. Much like other models we used a combination of trial and error and vintage documents such as those seen here.

300SL Pumps

Fuel Feed Pump

ANOTHER ESSENTIAL PART OF YOUR

FUEL INJECTION PUMP RESTORATION

Along with the fuel injection pump itself, the fuel feed pump is an essential but often overlooked part of Mercedes-Benz restorations. Despite appearances, this small attachment is anything but simple and requires just as much expertise to rebuild and restore as the fuel injection pump itself. Furthermore, because so few fuel injection pumps are restored in the first place, fuel feed pumps are even less likely to have received attention and regularly are found in poor condition negatively effecting the performance of the vehicle even after so-called full restoration projects. Even many fuel injection pump restorers have ignored the internal mechanics of the fuel feed pumps for decades, leading to inaccurate testing and calibration which leads to incorrect adjustments to get the car running more smoothly.

We not only restore fuel feed pumps using the same meticulous process as our fuel injection pumps, but we're also working on an exchange for fuel feed pumps that are beyond repair or the missing piece to complete your restoration.

Here you can see our fuel feed pump housing and some of the internal parts after going through the refinishing process. Each has been machined to exacting specifications for optimal performance and tested to ensure all refinished feed pumps operate appropriately.

If you take a look inside the fuel feed pump body you will see that we remachine the interior to remove any imperfections or wear to ensure ideal pressure and performance of the piston. We also refinish the surface, interior and threads of the piston itself so all parts are working at their optimal capacity.

Whether you need an entire fuel injection pump and all the accessories or just the fuel feed pump, contact us today to see what we have available and get your project scheduled.

Fuel Injection Pumps

Throttle Housing Jet Kit

Getting YOUR ENGINE IN TUNE WITH A CALIBRATED FUEL INJECTION PUMP

While a good fuel injection pump restoration can go a long way, if your throttle housing jets aren't providing the correct vacuum signal, the fuel injection pump can only do so much. Even if you think your vehicle ran well before, installing a restored pump introduces new variables which won't align with the wear of unrestored parts, and, as a result, your vehicle will run differently. Replacing the jets is the only way to ensure our calibration carries over to your specific engine performance. We offer full sets of throttle housing jets in a high-quality Haliburton case so that you can

ensure your pump is getting everything it needs to operate effectively

after installation.